Hotchkiss drive is the most widely used type of Rear axle drive. It is also simplest compared to Torque Tube drive.

In all the drives which are employed for rear axles, the springs take the weight of the body.

Types of Rear Axle Drives:

There are many types of drives, out of which two are important. They are

- Hotchkiss Drive

- Torque Tube Drive.

Let's dive into the concept of Hotchkiss Drive.

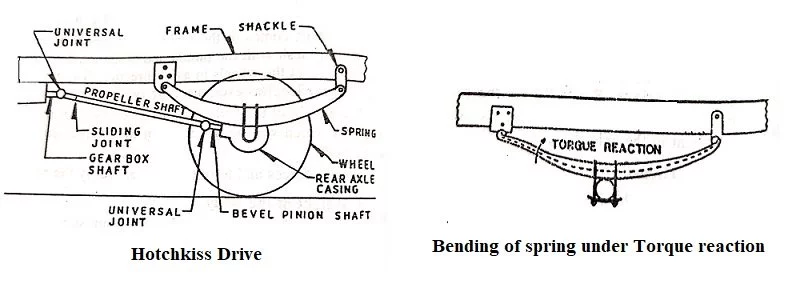

Line Diagram of Hotchkiss Drive:

The line diagram of Hotchkiss Drive is shown below whose parts are explained in a detailed way.

Parts of Hotchkiss Drive:

The parts of Hotchkiss Drive are as follows universal Joints – 2 No’s

- Propeller Shaft

- Sliding Joint of Propeller shaft

- Bevel Pinion Shaft

- Rear Axle Casing

- Wheel of the Vehicle

- Leaf Spring

- Frame

- Shackle

An explanation for the parts of Hotchkiss Drive:

The detailed explanation for the parts of Hotchkiss Drive is as follows.

Universal Joints:

The universal joint is a connection between two shafts whose axis is inclined to each other. Two Universal Joints are used at the beginning and end of the propeller shaft.

Propeller Shaft:

It is also known as drive shaft which is used to transmit the power from the engine shaft to the rear axle casing.

Sliding Joint of Propeller Shaft:

The main purpose of the sliding joint in the propeller shaft is to enlarge and reduce the length of the propeller shaft while the vehicle is moving on uneven roads.

Bevel Pinion Shaft:

The bevel pinion is placed at the end of the propeller shaft to transmit the power from the engine to the differential. [The bevel pinion is in direct contact with the crown wheel of the differential.]

Rear Axle Casing:

It is the casing that was present at the center of the rear axle which consists of the mechanism of differential and its connection with bevel pinion shaft.

The leaf spring is also connected to the rear axle casing.

Wheel of the Vehicle:

The power generated at the engine shaft is to be transmitted finally to the wheels of the vehicle via the axles.

Leaf Spring:

It plays a vital role in the suspension system. It carries the load of the vehicle, Driving Thrust, Torque Reaction, and the Side Thrust also while it is under motion. It is fixed rigidly in the middle of the rear axle.

Frame:

All the components of the Hotchkiss drive are attached to the frame only.

Shackle:

One end of the leaf spring is connected to the frame (which is fixed) and the other end is connected to the shackle for a slight motion of spring w.r.t. the uneven roads.

Working Principle of Hotchkiss Drive:

The parts which are presented above constitute the Hotchkiss drive. The power generated at the engine is to be transmitted to the Gearbox and from there it is transmitted to the rear axle casing via propeller shaft.

The Propeller shaft is fixed in between two universal joints and a sliding joint.

In the case of Hotchkiss drive, the entire load of the vehicle is managed by the leaf spring. Not only the weight of the body but also Driving Thrust, Torque Reaction, and the Side Thrust were managed by the springs of the vehicle.

The driving thrust is transmitted to the frame by the front half of the springs and due to Torque reaction, the spring deflects as shown in the figure and this Torque reaction is taken up by the springs.

Similarly, the springs would deflect in the opposite direction to take up the braking torque.

Due to this Torque reaction and braking torque, the spring deflects as shown in the above figure. Due to this, the bevel pinion also changes its position.

Therefore, if only one universal joint is employed at the end of the propeller shaft, it will bend w.r.t. the various reactions.

To avoid the bending of the propeller shaft, another universal joint at the end of the propeller shaft is used.

During the movement of the vehicle, the rear axle moves up and down and it has to move in a circle with the front spring support at the frame as a centre.

But for the motion of propeller shaft, the center is at the front universal joint which means that during the movement of the rear axle the length of the propeller shaft has to vary and this can be provided employing sliding joint in the propeller shaft.

The sliding joint is used to increase and decrease the length of the propeller shaft during running on uneven roads.

Advantages of Hotchkiss Drive:

The advantages of a Hotchkiss drive are as follows.

- It is easy to manufacture and assemble

- high load carrying capability

- Simple design

Disadvantages of Hotchkiss Drive:

The disadvantages of a Hotchkiss drive are as follows.

- It can occupy more space compared to other suspension systems.

- Suspension weight is high.

Applications of Hotchkiss Drive:

The applications of Hotchkiss drive are as follows.

- As of 2016, the design is common in sport utility vehicles and pick-up trucks.

This is a detailed explanation of the Hotchkiss drive.