Lubrication is required for vehicle engines since they contain two or more robing, moving parts. These pieces promote friction and heat, resulting in significant wear and tear on the pairs. Lubrication is essential in automobiles because it improves engine efficiency and lifetime. When two moving parts are separated by a lubricant film, they are no longer connected. That is, they have no physical contact with one another.

What is Engine Lubrication?

Functions of Engine Lubricating System

Below are the functions of lubricating oil in an engine:

- Engine lubrication is the separation of robing metal parts by the passage of lubricating chemicals between them. Lubricants are available in liquid, solid, and gas forms, with liquid being the most commonly utilised in engines.

- Oil acts as a cleaning agent in engines by transporting dirt particles to the oil pan. Smaller particles are filtered out by the oil filters, while bigger particles are kept in the oil pan.

- Engine lubrication also works as a cooling system. Lubricating oil cools the engine's moving parts and transfers heated oil into the colder oil in the oil pan.

- The oil forms a seal between the cylinder walls and the piston rings. It also decreases exhaust gas blowby.

- Oil is used to fill the space between the revolving journals and the bearing. When the bearing is suddenly subjected to large loads, the oil acts as a cushioning agent. Oils help to prevent bearing wear.

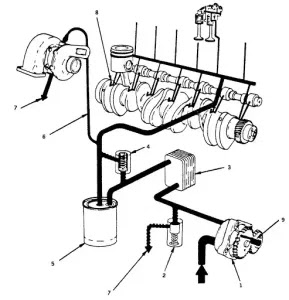

Major Parts of Engine Lubricating System

The following are lubrication system components:

Oil pan/sump:

Oil Pump:

Oil filter:

Oil Galleries:

Oil cooler:

- Crankshaft main bearings

- Big end bearings

- Piston pins and small end bushes

- Piston rings

- Timing Gears

- Air-compressor piston and bearings (in commercial vehicles for air-brake)

- Camshaft and bearings

- Valves

- Cylinder walls

- Oil pump parts

- Water pump bearings

- Turbocharger bearings (if available)

- Vacuum pump bearings (if available)

- In-Line Fuel Injection Pump bearings

- Tappets and push-rods

Types of Engine Lubrication Systems

Below are the types of engine lubrication systems:

Mist Lubrication System: This type is utilised in two-stroke engines to combine oil and gasoline. The mixture is created by the carburetor.

The fuel is vaporised, and the oil enters the cylinder as a mist through a crank base. The connecting rod, piston ring, piston, and cylinder are all lubricated by oil in the crank base.

The Wet Sump Lubricating System (WSLS) is usually found adjacent to or near the crankshaft. It is located at the bottom of the engine and is equipped with a single oil pump. This pump is responsible for moving oil through the oil galleries. The construction is simpler and more limited in scope.

Dry Sump Lubricating System: A dry-sump system has an oil reservoir that is not at the engine's bottom. Two oil pumps are used to keep the oil moving throughout the engine. The system is more complicated and costly to design. The pan, on the other hand, has more design freedom because it is in an odd location. It is frequently found in high-performance engines.

Lubricating System in Two-stroke and Four-stroke engines

The operation of two-stroke and four-stroke engines is very different, as is their lubrication system. Internal combustion engines generate mechanical power by utilizing the chemical energy inherent in hydrocarbon fuels. Lubrication is required for the operation of various engine components in order to minimize wear and tear and maximize engine efficiency.

Lubrication in Four-stroke Engine

Oil is stored in an oil sump or pan in four-stroke engines for lubrication. The oil circulates within the engine by splash lubrication or a pressurised lubrication pump system, which manufacturers prefer. Although the two can coexist in a single engine.

Two-stroke Engine Lubrication

Two-stroke engines, in general, wear out faster since they lack a lubricating supply. However, there is a high-quality oil that decreases engine wear greatly.

Two-stroke engines use a total-loss lubrication system to receive oil beneath the crankshaft. This lubricating system combines oil and fuel to deliver both energy and lubrication to the engine.

The two agents are blended in the intake tract of the cylinder and lubricate components such as the crankshaft, connecting rod, and cylinder walls.

Two-stroke engines with oil injection inject oil directly into the engine, where it combines with the fuel. Oil and fuel are combined in a premix two-stroke engine before being poured into the fuel tank.

This concludes the "Engine Lubricating System" article. I hope you have gained information; if so, please leave a comment, share, and promote this site to other technical students. Thanks!